Recycling thermoset GFRP-waste with Conenor patented technology - Wish to buy the patent ?

Lipor Park, Baguim do Monte, Portugal

Warwick University Campus, UK

RECYCLed THERMOSET GFRP-WASTE reinforcing THERMOPLASTIC COMPOSITES

download leaflet (pdf) - presentation at WindEurope EOLIS-seminar Nov 2021

What is FRP ? (source: WikipediA) Fibre-reinforced plastic (FRP) (also fibre-reinforced polymer) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (GFRP), carbon, aramid, or basalt. The polymer is usually an epoxy, vinylester or polyester thermosetting plastic; phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries.

Wind energy is 100% green energy - but what about the materials the turbines are built of ? Wind turbine blades, longest over 100 meters and in weight close to 50 tons each, are made of FRP and yet today considered non-recyclable. Rapidly growing wind energy sector all over the world must find a solution for recycling the blades made of FRP to remain a truly green alternative ! see what Conenor and Ecobulk-project are aiming up; http://www.ecobulk.eu/public/news/newsletter-1-developing-circular-framework-ecobulk-takes-lead

With a competitive and practical recycling solution composites have a great future ! Global volumes of FRPs are rapidly increasing and mainly replacing metals and wood. The challenging drawback of FRPs is that yet till today there has been no feasible recycling solution existing for them. The invention of Conenor is a simple and low cost thermo-mechanical process to produce homogenous reinforced material utilizing FRP-waste (without grinding into powder) for extruded and moulded thermoplastic composites in single- and/or multilayer structures.

THE KNOW-HOW IS AVAILABLE FOR ANYONE INTERESTED TO TAKE BENEFIT OF IT ! PLEASE CONTACT

*** UTILIZATION OF OWN MANUFACTURING WASTE FOR FRP-PRODUCT MANUFACTURERS ***

+++ NEW BUSINESS POTENTIAL FOR THERMOPLASTIC COMPOUND MANUFACTURERS +++

### LOW COST REINFORCEMENT FOR WOOD-PLASTIC-COMPOSITE PRODUCT MANUFACTURERS ###

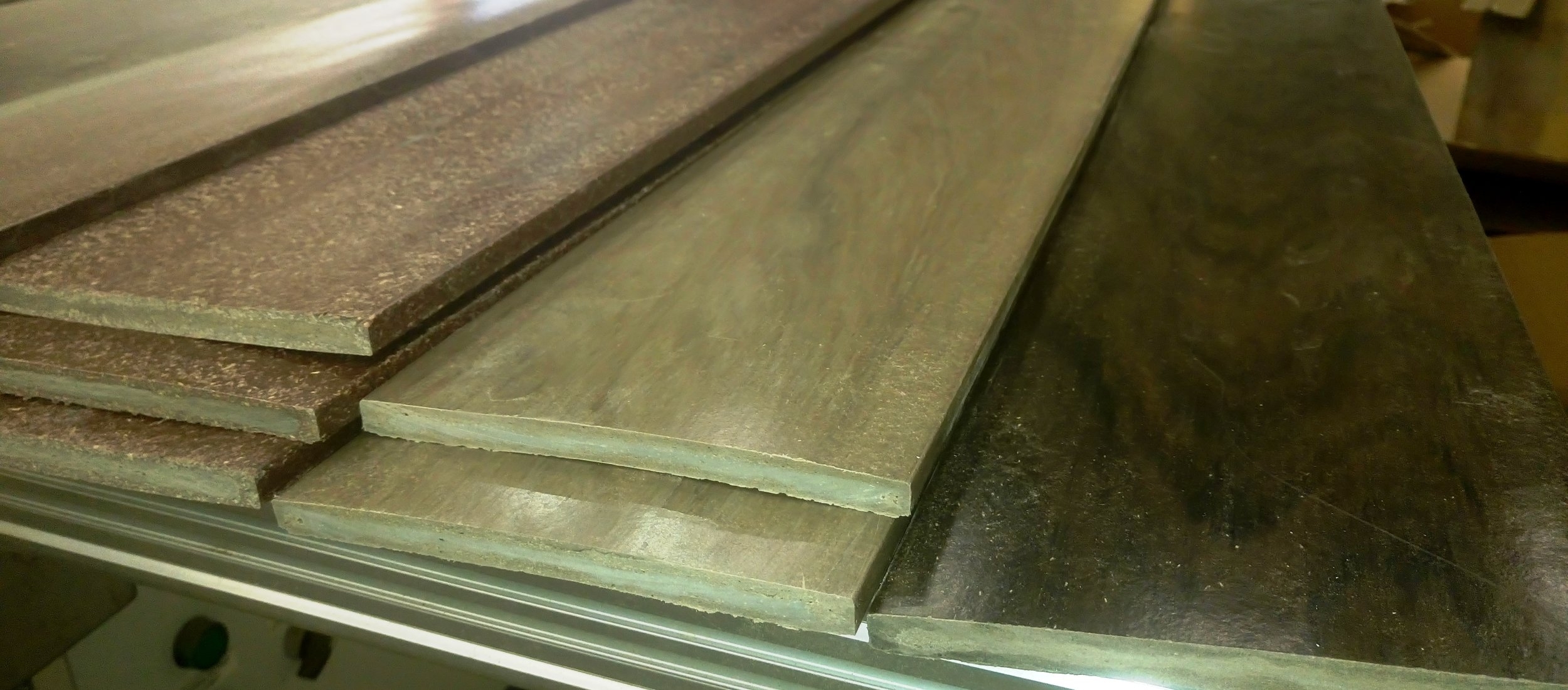

Panel core layer: Epoxy-glass fibre FRP-waste / recycled HDPE-plastic (70/30%)

Panel surface layer: Wood-Plastic-Composite WPC (waste wood / recycled HDPE-plastic 70/30%)

Illustrations in multilayer extrusions; panel dimensions 10x150 mm

/// SUSTAINABLE LOW COST REINFORCEMENT IN PLASTIC (PE, PP) DRAINAGE AND GRAVITY SEWER PIPE SYSTEMS ///

CORRUGATED PIPES CHANNELS CHAMBERS & MANHOLES TANKS & SEPARATORS

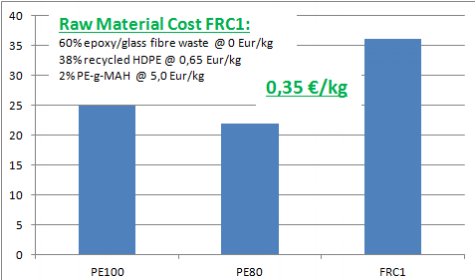

COMPARING STIFFNESS (E-MODULUS) OF FRC1 AT ITS GIVEN MATERIAL COST

COMPARING STRENGTH OF FRC1 AT ITS GIVEN MATERIAL COST

Hollow decking boards with thermoset FRP-waste (1/3) + wood fibres (1/3); on top multilayer with PPr (1/3) at core and HDPEr (1/3) at surface / on bottom single layer in HDPEr (1/3)

Multilayer solid board 120x30mm with FRP-waste both from manufacturing and EoL

ARTICLES FOR READING

Composite End-Use Applications http://www.jeccomposites.com/knowledge/end-use-applications

Composite Materials in Building and Construction Applications http://compositebuild.com/wp-content/uploads/2013/07/Composite-Materials-in-Building-and-Construction-Applications.pdf

Building on the advantages of composites in construction http://www.materialstoday.com/download/79511/

Composites Recycling: Where are we now ? https://compositesuk.co.uk/system/files/documents/Recycling%20Report%202016.pdf

Composite Materials: A Resource Efficiency Action Plan https://connect.innovateuk.org/documents/3228340/3708155/Composites%20REAP%20021%20FINAL.pdf

Recycling composites commercially http://www.materialstoday.com/composite-industry/features/recycling-composites-commercially-part-1/ http://www.materialstoday.com/composite-industry/features/recycling-composites-commercially-part-2/

Glass fibre reinforced thermosets: recyclable and compliant with the EU legislation http://www.avk-tv.de/files/20131125_industry_position_paper_on_recycling_2011_3.pdf

End of Life Options for Composite Waste - Recycle, Reuse or Dispose ? https://compositesuk.co.uk/system/files/documents/End%20of%20Life%20Options.pdf

Kielto ei pure – lujitemuovia päätyy edelleen kaatopaikalle http://yle.fi/uutiset/3-8831043

photo by Anna Jimenez Calaf