Public Projects

Conenor actively participates in preparation and execution of public funded R&D projects aiming to improve material recovery and their efficient use and recycling by the development and use of composite extrusions.

Recent active public R&D projects :

EU/FP7 project IRCOW (2011-2013);

Innovative Strategies for High-Grade Material Recovery from Construction and Demolition Waste, click www.ircow.eu

read an article OPPORTUNITIES FOR RECYCLING CONSTRUCTION AND DEMOLITION WASTE (C&DW) INTO WPCs, click here

EU/FP7 project OSIRYS (2013-2017);

Forest based composites for façades and interior partitions to improve indoor air quality in new builds and restoration

Conenor R&D task; fire retardant material & extruded panel (class B,d0,s2)

click www.osirysproject.eu see fotos of two demos (Tartu/Estonia and SanSebastian/Spain)

Multi-Layered Façade displayed at JEC World 2017

Project OSIRYS - with Conenor extruded fire proof (B2,d0,s2) biobased composite panels - selected as Success Story read news here at EU Commission web pages

EU/Horizon 2020 project HISER (2015-2019);

Holistic Innovative Solutions for an Efficient Recycling and Recovery of Valuable Raw Materials from Complex Construction and Demolition Waste

The main goal of HISER project is to develop and demonstrate novel cost-effective technological and non-technological holistic solutions for a higher recovery of raw materials from ever more complex construction and demolition waste (C&DW), by considering circular economy approaches throughout the building value chain (from the End-of-Life Buildings to new Buildings).

The first demonstration was constructed in November 2017 for the Finnish State Forestry Department Metsähallitus; a shed for firewood - the very first construction ever built in Finland completely from WPCs ! see more fotos

The second demonstration in spring 2018 will be a WPC-stall for three horses at Rautalammin Ratsastuskeskus

click www.hiserproject.eu

NEWS click; High strength wood-plastic composites recycled from construction and demolition wood waste

Latest HISER news February 2018 https://mailchi.mp/hiserproject/whats-new-in-hiser-project-check-it-out

Finland/SHOK project ARVI by Cleen (2014-2017), Conenor acting as sub-contractor

The research in ARVI program focuses on systemic assessment of material recovery and recycling opportunities. Attention is very much laid on studying recycling of such materials and elements. Detailed knowhow is created on material compositions and structures, and processing technologies are studied to modify the materials for reuse purposes or to capture valuable components found in very small amounts in complex matrixes. In addition, different types of modelling and assessment methodologies for chemical, process, LCA, environmental footprint and techno-economical calculations are combined to perform sopficated overall analyses of material value chains.

The objective of the ARVI (Material Value Chains) research program is to build a solid and broad competence background, i.e., an innovation platform, based on which the Finnish material recovery industry may extend their businesses and improve competitive positioning in the global markets. The program creates data, assessment tools and concepts for the value chain management and processing of materials to enable for the Finnish companies to expand and deepen their knowhow and to find out new technologies, process solutions and services as well as new ways to combine them to meet the requirements of future markets.

EU/Horizon 2020 project ECOBULK (2017-2021)

ECOBULK through a large scale demonstration effort will contribute to “closing the loop” of composite products in the automotive, furniture and building sectors by promoting greater re-use, upgrade, refurbishment and recycle of products,parts, and materials.

The methodology will embrace and focus on large scale demonstration activities in 7 countries and more than 15 demonstrators to address the key components of the circular economy solutions

Conenor is acting as leader for work package WP4 for all demonstration activities and in its own developments will focus in composite materials, formulations in agglomeration technique and extrusions in various single- and multilayer product structures and especially demonstrating new techniques in recycling thermoset FRP-waste reinforced thermoplastic materials from wind turbine blades

read article in Waste Management World issue MAY-JUNE 2018

Among other several demonstrations in Europe, the Finnish Ecobulk furniture and building demonstrations for outdoor benches, shelters and cabins will take place at KymiRing racing track under construction at Kausala to start at 2020

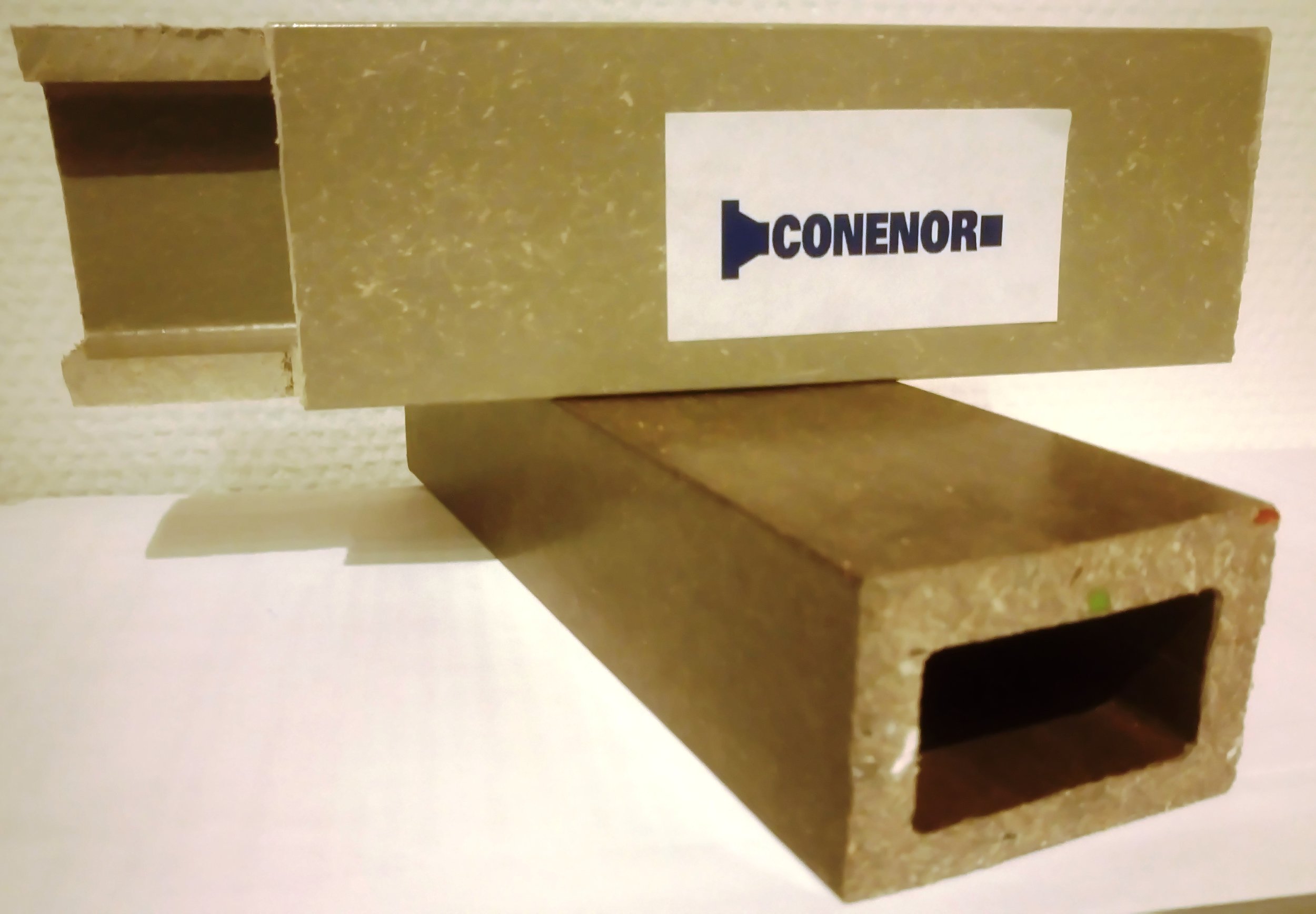

Extruded profiles from construction & demolition waste wood and thermoplastics reinforced with wind turbine blade waste (G-FRP)

Extruded profiles from French wood furniture waste and Brasilian biobased polyethylene

Drinking fountain at LIPOR park, Portugal

Rest place around a tree at LIPOR park, Portugal

Gazebos at three Universities Warwick, Coventry and Cranfield, UK

Flagman shelters at KymiRing track, Finland

Photo by John Loo